Last Updated on May 19, 2023 by Leepu Da Maxim

Well, the international standard weight for a train wheel is 340 kg. But the exact weight of a train wheel depends on the size of the train. For example, the weight of a tram wheel or light train is 50-100 kilograms. On the other hand, the weight of a heavy train wheel is around 200-300 kilograms.

Key Takeaways

- The weight of a train wheel can be anywhere from 400 pounds (181.437 kg) to 2,000 pounds (907.1847 kg)

- The standard train wheel weight ranges from 235 pounds to 480 pounds

- The lighter-weight train wheel assemblies have an average load capacity of 10,000 pounds

- The train wheels are made of high-strength steel and no other materials are mixed because train wheels must substantiate a large amount of weight

Different Types of Train Wheel Weights

Standard Train Wheel Weight

Standard train wheel assemblies can weigh 235 pounds (106.5942 Kg) to 480 pounds (217.724 Kg). The weight is due to the size and material used and the number and thickness of the axles.

Lighter-Weight Train Wheel Weigh

Train wheel assemblies are lighter because they use smaller-diameter wheels. These components are designed not to suffer the weight of the train but rather to run smoothly and efficiently.

The lighter-weight train wheel assemblies have an average load capacity of 10,000 pounds (4535.924 Kg), while the heavier assemblies have an average capacity of 40,000 pounds (18143.695 Kg). The lighter-weight trains are mainly used in urban areas with lower traffic volumes.

KLW Wheels Weigh

Wheels are a crucial part of a car’s suspension and steering system. They also hold the weight of the assembly, which mostly depends on the type of wheel being used. For example, KLW wheels by themselves weigh between 363 lbs (164.654 Kg) to more than 2,300 pounds (1043.262 kg).

Wheels are an important part of the function of a vehicle. This includes the weight of the wheel assembly, which is determined by the type of wheel being used. Depending on what type of wheel is being used, they will have different weights.

Individual Wheel

A wheel can be an individual wheel that is not attached to an axle. The weight of the wheel can be anywhere from 400 pounds (181.437 kg) to 2,000 pounds (907.1847 kg). A wheelset is a collection of two or more wheels connected together in a way that allows them to rotate in unison and with equal speed.

What Materials Are Used To Make A Train Wheel?

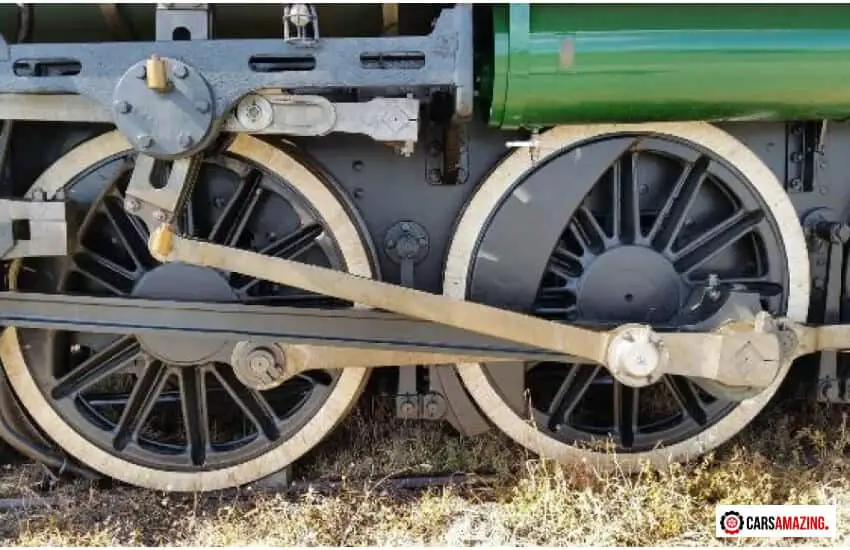

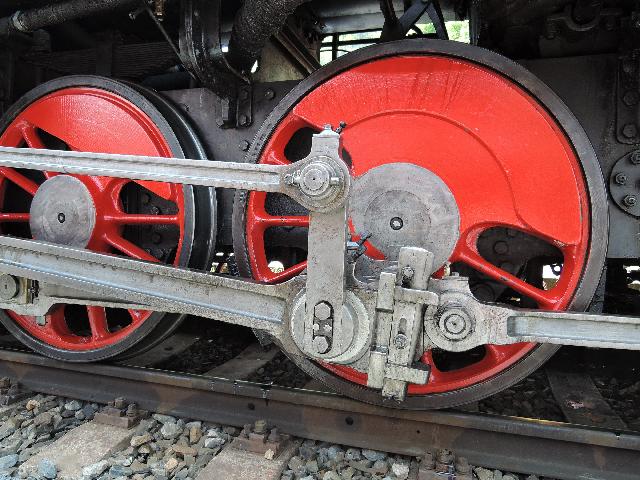

In principle, the wheels of a locomotive are made of high-strength steel. It is actually risky to use other materials since a train wheel must substantiate a large amount of weight. For this reason, wheels are manufactured that are usually connected with the same axle. In this way, the axle allows two wheels to be synchronized efficiently.

Measurement of train wheel weight

The weight of a train wheel is an important factor to consider, as it influences the overall performance and efficiency of the locomotive. Train wheel weight is determined by several aspects such as size, material, and design, but generally ranges from 8 tons for smaller locomotives to 35 tons for large ones. A typical 36-inch train wheel may weigh around 900 pounds when new, with the wheel becoming lighter as it wears down over time. These massive wheels are made from high-quality steel, designed to withstand immense stress and provide a smooth, efficient ride on the rails. Consequently, understanding the weight of a train wheel is essential for safe and effective railway transportation.

Range of train wheel weights

The weight of a train wheel can vary greatly depending on factors such as size and design. Typically, train wheels can range from smaller locomotives weighing around 8 tonnes to larger ones weighing up to 35 tonnes. As a more specific example, a new 36-inch train wheel could weigh roughly 900 pounds, with worn wheels being lighter. Bear in mind that these weights are for the wheels alone, not including axles or other assembly components. Accurately determining the weight of a train wheel is important for ensuring proper transportation and handling, as well as maintaining safety and performance on the rails.

Factors affecting train wheel weight

1. Material Composition: Train wheels are typically made of high-quality steel alloys, which determine their overall weight. Different types of steel, along with additional materials used for reinforcement, can affect a wheel’s weight.

2. Wheel Size: The size of railway wheels varies to accommodate different train types and purposes. Larger trains that carry heavy cargo will require larger, thicker, and heavier wheels to support the load. Thus, weight greatly depends on the wheel’s dimensions.

3. Wear and Tear: As train wheels are constantly in use, they experience wear and tear from friction against the tracks. Consequently, a worn-out wheel will weigh less in comparison to a brand new one. Regular maintenance and replacement are necessary to ensure safety and efficiency.

Significance of rail wheels in transportation

1. Enhanced Efficiency: Rail wheels made of steel reduce rolling friction, which allows trains to carry heavier loads efficiently. This makes rail transportation one of the most energy-efficient options for moving large goods.

2. Precise Navigation: Rail wheels do not require manual steering, as the tracks provide navigation needed for the train’s movement. This ensures accurate and efficient travel through predetermined routes.

3. Durability and Low Maintenance: Train wheels can last up to 700,000 miles before requiring replacement, making them an enduring component of the railway system. The use of steel, a highly durable material, also ensures lower maintenance requirements.

4. Safety and Stability: The unique design of rail wheels, featuring a flange on one side and a conical shape, keeps trains safely running on the tracks even in challenging conditions such as sharp bends or strong side winds. This promotes stability and reduces the risk of derailments.

Material and profile of railway wheels

Railway wheels are made from high-quality steel alloy, which ensures they can withstand the immense stress and weight that comes with being a part of a train’s structure. The material used for the wheels provides the necessary durability and strength for efficient and safe travel. Wheels are initially cast or forged and then heat-treated to reach a specific hardness level. They are machined using a lathe to create a standardized profile, ensuring a proper fit on the rail tracks. The wheel profile is essential for maintaining correct alignment, reducing wear on the tracks, and preventing derailments. In summary, the material and profile of railway wheels are key factors in ensuring smooth, safe, and efficient train travel.

How Much Does An Amtrak Train Wheel Weigh?

The weight of a train wheel, specifically an Amtrak train wheel, plays a crucial role in the overall stability and performance of locomotives. Generally, a single train wheel, not attached to an axle and another wheel, weighs between 800 and 900 pounds (362 to 408 kg). However, wheelsets, which consist of pairs of wheels joined together by an axle, weigh over 2,000 pounds (907 kg). The weight of an Amtrak train wheel can vary depending on factors like size and design, but it predominantly falls within this range. These steel wheels help ensure smooth and efficient movement while reducing rolling friction on the tracks.

References:

Hi, I’m Leepu Da Maxim, a dedicated car enthusiast with over 10 years of experience in this field, and I’m thrilled to share my passion and expertise with fellow car enthusiasts like you. My journey began in my hometown West Jordan, Utah, where my fascination with the mechanics and design of cars sparked at a young age. Over the years, this passion has evolved into a commitment to providing accurate, insightful, and engaging information about all things automotive through CarsAmazing.